RO (Reverse Osmosis) and DI (Deionisation) systems from Waterworks purify tap water into 0-TDS pure water for streak-free, spotless results. Designed for professional window cleaners, these systems reduce chemical use, improve efficiency, and deliver consistent cleaning performance for every route — from compact vans to large commercial setups.

Key Facts

- RO and DI filtration combine membrane and resin stages to achieve 0 ppm pure water.

- DI-only systems are ideal for soft-water areas; RO/DI setups perform best in hard-water regions.

- Chemical-free cleaning protects glass, frames, and the environment.

- Waterworks systems are available in 500 L, 750 L and 1000 L capacities.

- Built for professional reliability with manual or electric hose-reel options.

In This Article

Introduction – Why Pure Water Filtration Matters

Every professional window cleaner knows that using ordinary tap water often leaves behind streaks and mineral marks. That’s because tap water naturally contains dissolved solids such as calcium and magnesium, which dry on the glass surface and create visible spotting.

Pure-water filtration eliminates this problem by removing these minerals entirely — producing 0-TDS water that dries crystal clear. Whether you clean residential properties or large commercial buildings, pure water saves time, reduces the need for chemicals, and delivers consistently spotless results.

At Waterworks, our RO and DI systems are purpose-built for professional window cleaners who value quality, reliability, and long-term performance. Each system is engineered to make your cleaning workflow smoother — from filling your tank to rinsing glass — ensuring every job looks perfectly finished without the use of detergents or additives.

What Are RO and DI Systems? (Pure Water Filtration Explained)

Pure-water systems use advanced filtration technology to remove impurities from tap water, creating mineral-free water that leaves no residue when it dries on glass. For professional window cleaners, this is the key to achieving streak-free, spotless results on every surface.

What Is Reverse Osmosis (RO) Filtration?

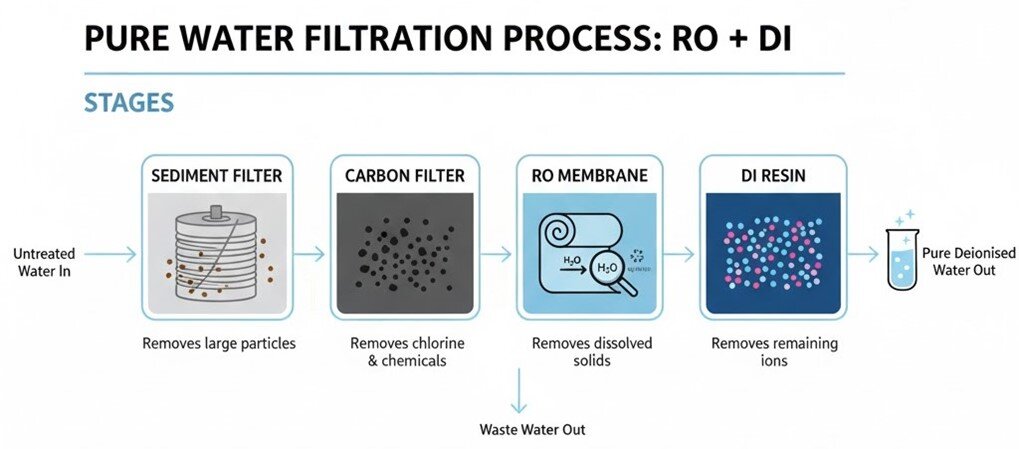

Reverse osmosis is a multi-stage filtration process designed to treat hard or high-mineral water.

An RO system typically includes:

- Sediment and carbon pre-filters that remove larger particles and chlorine.

- A semi-permeable membrane that separates up to 95–99% of dissolved solids from water.

- An optional booster pump to maintain steady pressure and ensure consistent output.

At Waterworks, RO systems are designed for professional use, providing steady production of purified water suitable for van-mounted or delivery-only setups. The RO stage significantly reduces TDS (Total Dissolved Solids) before the water passes into the final polishing stage.

What Is Deionisation (DI) Filtration?

Deionisation, or DI filtration, uses a vessel filled with mixed-bed resin that captures the remaining ions left after pre-filtration or RO treatment. The result is 0-TDS pure water that dries perfectly clear without leaving any mineral residue.

A DI-only system can be used in soft-water regions or for smaller setups where water hardness is naturally low. It’s lightweight, portable, and ideal for professionals who need quick, chemical-free cleaning on the go.

Why 0-TDS Water Delivers Spot-Free Results

When water contains minerals, those minerals stay on the glass as spots once the water evaporates. 0-TDS water, however, contains no solids — so nothing is left behind after rinsing. This is why pure-water cleaning has become the professional standard across the industry, offering a faster, safer, and eco-friendly alternative to traditional methods.

RO vs DI Systems – Core Differences

Both RO (Reverse Osmosis) and DI (Deionisation) systems purify water to create a spotless, streak-free finish — but they do so in different ways.

Understanding how each one works helps you choose the right setup based on your local water hardness, job volume, and system type.

Water Hardness and Filtration Choice

Water hardness directly affects how much mineral content needs to be removed from tap water.

- In soft-water areas, DI-only systems are usually sufficient because the incoming TDS levels are naturally lower.

- In medium to hard-water areas, RO/DI systems perform better, as the RO membrane handles most of the mineral removal before the DI resin polishes the water to 0 TDS.

This combination reduces the workload on the resin, helping maintain consistent water quality for longer periods.

Output Quality and Flow Speed

RO/DI systems are designed for higher output quality, providing stable 0 TDS readings suitable for long routes or dual-operator setups.

DI-only systems are faster to deploy and ideal for smaller setups, but the resin depletes faster in hard-water regions.

Both deliver spotless results when maintained properly — the main difference lies in how efficiently they achieve that purity.

Running Costs and Maintenance

RO/DI systems typically have a higher initial cost but lower long-term resin consumption.

DI-only systems are more affordable upfront and require minimal hardware, but resin replacement can become frequent if water hardness is high.

For professionals operating daily, an RO/DI setup offers better cost control over time.

System Size and Setup Options

Waterworks provides both van-mounted and delivery-only systems, giving professionals flexibility based on their routes.

- RO/DI setups: Best suited for medium to large vans or commercial teams that handle multiple sites daily.

- DI-only systems: Lightweight and portable — ideal for one-man operations or occasional use.

Comparison Overview

Feature | RO System | DI System | RO/DI Combination |

Best For | Hard-water regions | Soft-water regions | Medium to hard-water regions |

Initial Cost | Higher | Lower | Moderate |

Resin Usage | Low | High | Low |

Maintenance | Periodic filter and membrane changes | Resin replacement | Filter + resin care |

Portability | Fixed or van-mounted | Portable | Van-mounted |

Output Water | 5–20 ppm before DI | 0 ppm (shorter lifespan) | 0 ppm consistent |

Ideal User | Commercial setups | Small operators | Professional cleaners |

RO and DI both achieve the same result — pure, spotless water — but your region’s water hardness and cleaning frequency will determine which is more efficient for you.

Waterworks systems are designed to offer both options, ensuring that every professional can build a setup that fits their routes, vehicle, and workload.

Key Benefits of Using RO and DI Systems for Window Cleaning

Professional window cleaners choose RO and DI systems because they combine cleaning quality with long-term efficiency. Instead of using detergents or traditional soap-and-squeegee methods, pure-water cleaning provides a chemical-free way to achieve spotless, streak-free glass every time.

1. Spot-Free, Professional Results

0-TDS pure water dries naturally without leaving any mineral residue or streaks, producing a clear, reflective finish that enhances your professional image. Whether you’re cleaning office windows, conservatories, or high-level glass, the result is always consistent and spotless.

2. Chemical-Free, Eco-Friendly Cleaning

Pure-water cleaning removes the need for chemical detergents. This makes every job safer for operators and clients, while also protecting building surfaces, seals, and surrounding landscaping. It’s an environmentally responsible approach that aligns with modern sustainability standards.

3. Faster Workflow and Reduced Downtime

RO and DI systems simplify cleaning routines — no need to mix solutions or wipe down residue.

Water-fed poles combined with pure water allow you to clean faster, especially on large or high windows. Less time per job means more completed routes each day.

4. Lower Running Costs

Because RO membranes handle most of the filtration process, resin consumption in RO/DI setups remains minimal. Over time, this reduces replacement frequency and overall operating costs. For regular commercial work, the difference in efficiency quickly pays off.

5. Reliable Results in Every Region

Whether you’re operating in a soft-water area or a hard-water zone, there’s a Waterworks system designed for your conditions. DI-only systems keep operations lightweight and quick, while RO/DI configurations provide consistent, high-purity output where mineral content is higher.

Pure-water technology has become the modern standard in professional window cleaning — offering cleaner results, safer working practices, and measurable cost benefits.

Waterworks systems bring all these advantages together in purpose-built, long-lasting designs engineered for the demands of everyday cleaning professionals.

What Type of Pure-Water Filtration Do You Need? (RO/DI or DI-Only)

Choosing the right filtration setup depends on three key factors — your local water hardness, the number of jobs you handle daily, and how mobile your system needs to be. Selecting the right type early not only saves running costs but also ensures consistent, spotless results every time.

Step 1 – Check Your Local Water Hardness

Water hardness refers to the level of dissolved minerals (mainly calcium and magnesium) in your tap water.

- In soft-water areas, TDS levels are naturally low, which means a DI-only system is usually enough to achieve 0-TDS results.

- In medium to hard-water areas, an RO/DI setup is recommended — the RO membrane removes most minerals before the DI resin polishes the water.

💡 Tip: You can check regional water hardness through your local supplier’s data or with a handheld TDS meter.

Step 2 – Assess Your Cleaning Volume

If you’re cleaning windows occasionally or covering smaller domestic routes, a DI-only system keeps your setup light and fast to deploy.

For high-volume cleaning — such as commercial contracts or multi-operator vans — RO/DI systems provide consistent output and longer intervals between filter changes.

Step 3 – Consider Portability and Setup Style

Your cleaning route and working style determine which system fits best:

- Portable DI-only units are compact and easy to move — ideal for limited storage or mobile operators.

- Van-mounted RO/DI systems handle larger tanks (500 L, 750 L, or 1000 L) with integrated hose reels, making them suitable for continuous daily use.

Quick Decision Guide

Condition | Recommended Filtration | Why It Works |

Soft-water area | DI-only system | Simple, low maintenance, fast setup |

Medium-water area | RO/DI system | Balanced cost & performance |

Hard-water area | RO/DI system | Handles high TDS efficiently |

One-man mobile setup | DI-only portable unit | Compact and easy to transport |

Multi-operator van | RO/DI system | Continuous supply, reduced downtime |

Example Scenarios

- Small domestic routes: One-person team using a 25–50 L DI trolley.

- Medium-scale commercial work: 750 L van-mounted RO/DI system with electric reel.

- High-volume operations: 1000 L dual-operator RO/DI setup for continuous output.

By understanding your region’s water hardness and workflow, you can choose a system that gives you the best balance of performance, portability, and long-term savings.

Waterworks offers both RO/DI and DI-only systems, each built with professional-grade reliability for different cleaning routes and regions.

Maintenance & Best Practices

Keeping your RO and DI system properly maintained ensures consistent 0-TDS performance and extends the lifespan of every filter component. Regular checks prevent downtime, reduce running costs, and guarantee spotless glass with every clean.

Monitor TDS Levels Regularly

Use a handheld or inline TDS meter to monitor your system’s output water.

If readings begin to rise above zero, it’s a sign that the DI resin or filters may need replacement.

For professional users who work daily, checking TDS once a week helps maintain quality control.

Replace Filters and Resin When Needed

- Sediment and carbon filters protect the RO membrane by removing debris and chlorine; replacing them at regular intervals prevents early membrane wear.

- RO membranes require periodic flushing to remove trapped minerals and maintain flow efficiency.

- DI resin should be replaced when TDS readings rise, indicating saturation.

Maintain Water Flow and Pressure

RO membranes work best at a consistent pressure level.

If you notice slow water flow, check the booster pump and tubing for blockages or leaks.

Keeping correct pressure ensures steady filtration and optimises resin lifespan.

Troubleshoot Common Issues

Issue | Likely Cause | Quick Fix |

Low pressure or weak flow | Clogged pre-filter or pump issue | Check and replace filters; inspect pump connections |

Spots on glass | Rising TDS or exhausted resin | Test water with TDS meter and replace resin |

Uneven spray or rinse pattern | Blocked jets or kinked hose | Clean jets, check hose alignment |

Proper maintenance keeps your Waterworks RO or DI system working efficiently day after day, providing dependable pure water for every cleaning job.

Environmental and Safety Advantages

Pure-water cleaning isn’t just about cleaner glass — it’s also about creating a safer and more sustainable way to work. RO and DI systems support both operator safety and environmental responsibility, making them a smarter long-term investment for any professional cleaning business.

Eco-Friendly Cleaning with Zero Chemicals

Because RO and DI systems rely purely on filtered water, there’s no need for detergents or additives. This means fewer chemicals entering drains or surrounding soil during rinsing. It’s a cleaner, greener method that aligns with modern sustainability expectations and environmental standards.

Protects Surfaces and Building Materials

Detergent-free pure water is gentle on glass, seals, and window frames. Regular cleaning with pure water prevents residue build-up and reduces wear from repeated scrubbing or chemical reactions, helping to preserve building finishes over time.

Safer Working Conditions

Water-fed pole systems paired with RO or DI filtration allow professionals to clean high windows from the ground. This reduces the need for ladders and lowers the risk of falls or injuries. It’s a safer approach that meets modern site-safety expectations while keeping productivity high.

Reduced Water Waste

Because pure water rinses more efficiently, less water is needed per job. Controlled flow systems and adjustable pumps further help conserve resources — a small change that makes a big difference across multiple daily cleans.

Pure-water systems are now recognised industry-wide as the responsible standard — offering spotless cleaning results while promoting worker safety and environmental care. Waterworks systems are built to deliver that performance reliably, every day.

Essential Accessories for RO/DI Systems

A well-designed pure-water setup is only as good as the accessories that support it. Choosing the right components ensures steady flow, accurate readings, and minimal downtime — all crucial for maintaining professional standards on every job.

TDS Meters and Pressure Gauges

A TDS meter (Total Dissolved Solids) is essential for checking water purity. It helps you know exactly when resin or filters need replacing.

An inline pressure gauge monitors system performance and ensures your RO membrane is operating at the correct level, preventing unexpected drops in output.

Flow Controllers and Booster Pumps

Flow controllers let you adjust water output to suit the height or surface type you’re cleaning.

A booster pump maintains consistent pressure across long hose runs or multiple operators, ensuring stable filtration and faster rinsing.

Together, these accessories improve efficiency and protect your filters from strain.

Hose Reels and Tubing Management

High-quality hose reels — manual or electric — keep your workspace organised and extend hose life.

Waterworks hose reels are built for daily use and integrate smoothly with van-mounted systems, allowing fast deployment and tidy storage.

Using the correct hose diameter (6–8 mm internal) ensures balanced flow between the pump, pole, and brush jets.

Spare Parts and Fittings

Having essential spares like connectors, clamps, and brush jets prevents downtime during busy days.

Keeping a small maintenance kit in your van allows quick replacements so your workflow never stops mid-route.

Equipping your RO or DI system with the right accessories improves performance, saves time, and reduces wear on critical components. Waterworks supplies every part you need — from flow controllers to reels — engineered for seamless compatibility and long-lasting reliability.

Frequently Asked Questions

How do RO and DI systems produce pure water?

RO systems use a semi-permeable membrane to remove most minerals and impurities from tap water. The water then passes through DI resin, which captures any remaining ions — producing 0-TDS pure water that dries clear on glass.

Can I use DI-only filtration in hard-water areas?

DI-only filtration works best in soft-water regions. In hard-water areas, the resin depletes quickly, making RO/DI systems more efficient and cost-effective. The RO stage reduces minerals first, helping the resin last longer and maintain consistent purity.

How often should resin and filters be replaced?

There’s no fixed timeline — replacement depends on water hardness and system use. Most professionals check TDS levels regularly and replace resin or filters when readings rise above zero, following Waterworks product maintenance guidelines.

What TDS reading ensures streak-free results?

0-TDS water is the professional standard for pure-water cleaning. Any reading above zero indicates dissolved solids that can leave light spotting or streaks once the water dries.

Why is a booster pump important for RO systems?

A booster pump maintains consistent water pressure, which helps the RO membrane operate efficiently. Proper pressure ensures steady water production and prevents early membrane wear.

Do RO/DI systems work for solar-panel cleaning too?

Yes — the same 0-TDS pure water used for window cleaning is also ideal for solar panels. It removes dust and residue without chemicals, protecting panel surfaces while improving cleaning results.

How can I estimate running costs for my system?

Running costs depend on water hardness, resin usage, and filter replacement frequency. Regular maintenance and pressure checks help lower long-term costs and keep system performance stable.

Pure-water systems from Waterworks are designed for professionals who value reliability, safety, and spotless results. Whether you choose a compact DI-only setup or a complete RO/DI system, consistent maintenance ensures your equipment performs at its best.

Build Your RO/DI System with Waterworks

Choosing the right pure-water system can completely transform how efficiently you work. Whether you operate in a soft-water area where a simple DI-only setup is enough, or in a hard-water region that demands full RO/DI filtration, Waterworks has a professional system built for your workflow.

Each setup is engineered with precision — combining quality components, durable tanks, and easy maintenance access to ensure years of reliable performance. From compact 500 L systems to 1000 L commercial configurations, every Waterworks system is designed to deliver crystal-clear, streak-free results day after day.

Explore complete RO systems built for hard-water regions and high-demand cleaning routes.

Find lightweight DI-only systems ideal for soft-water areas and mobile operators.

Use the Waterworks System Builder to create a setup tailored to your vehicle, workload, and budget.

By investing in the right pure-water filtration, you’ll save time, reduce maintenance costs, and deliver the spotless finish your clients expect.

Waterworks — built for professionals who expect more from every clean.