Many professionals waste money on the wrong window cleaning supplies. Waterworks reveals the five most common mistakes cleaners make when buying equipment — from cheap reels to poor filtration choices — and how to avoid them with durable, pure-water-ready systems built for performance and reliability.

Key Facts

- Wrong cleaning solutions and low-grade tools reduce glass clarity and lifespan.

- Buying cheap reels or fittings increases maintenance costs over time.

- Safety gear and accessories are critical but often overlooked.

- Always match pumps, hoses, and reels for correct compatibility.

- Waterworks supplies pure-water systems, reels, poles, and spares tested for commercial use.

In This Article

Why Smart Purchasing Matters

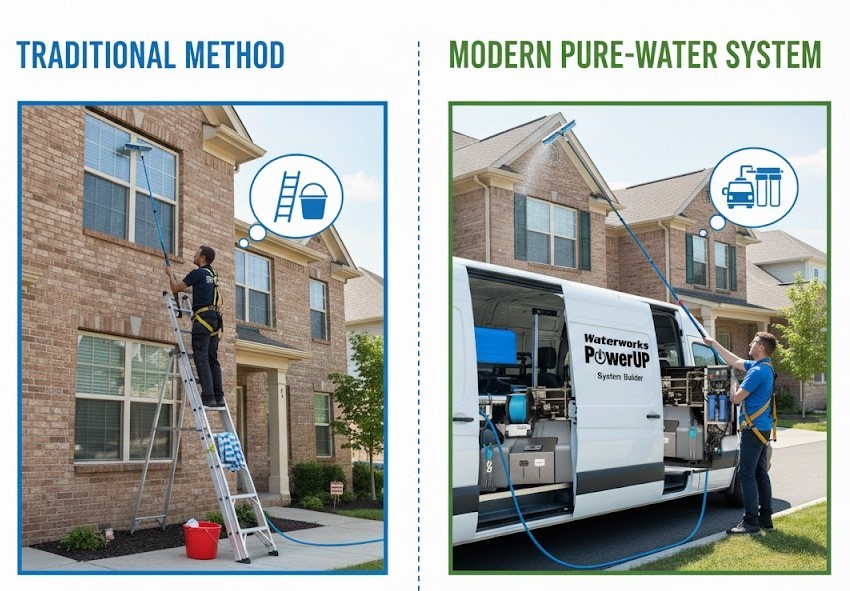

Professional window cleaning relies on precision — the right tools can make or break your results. The poles, reels and filtration systems you choose affect speed, safety and the quality of every clean. Yet many professionals still buy window cleaning supplies without checking compatibility, durability or long-term value.

At Waterworks Window Cleaning, we work with cleaners across the UK to help them select equipment that performs flawlessly day after day. From van-mounted pure-water systems to high-quality reels and accessories, we make it easy to build setups that save time and increase profits.

In this guide, we highlight the five most common mistakes professionals make when buying window cleaning supplies, and how you can avoid them to protect your investment and achieve spotless, streak-free results.

Mistake #1 – Buying the Wrong Cleaning Solution

Many professionals still purchase detergents or household chemical mixes designed for domestic glass.

These products often contain ammonia or surfactants that leave residue, attack rubber seals and frames, and shorten the life of resin inside de-ionising units.

Modern pure-water window cleaning systems remove the need for any soap at all.

Filtered, mineral-free water naturally dissolves dirt and dries clear without streaks — giving a cleaner result and protecting every surface you touch.

Using ordinary tap water or harsh cleaning liquids can also raise your TDS (Total Dissolved Solids) level, meaning glass dries with spots or cloudy marks.

Professional cleaners should always test their output water and maintain filters to keep TDS = 0 ppm.

How to Avoid This Mistake

- Choose pure-water filtration systems built for professional use.

DI Systems (Deionising) for soft-water regions.

RO/DI Systems (Reverse Osmosis + De-Ionising) for hard-water areas. - Never mix chemicals with pure water.

This neutralises filtration benefits and can corrode internal fittings. - Inspect your filters and resin regularly.

Replace resin when TDS > 010 ppm for best clarity.

Recommended Waterworks Solutions

Reverse Osmosis Systems — for high-volume, hard-water operations.

Deionising Systems — compact, cost-effective options for soft-water routes.

Both deliver ultra-pure 0 TDS water that ensures a streak-free finish and protects the integrity of your window-cleaning equipment.

Mistake #2 – Choosing Low-Quality Equipment or Worn-Out Tools

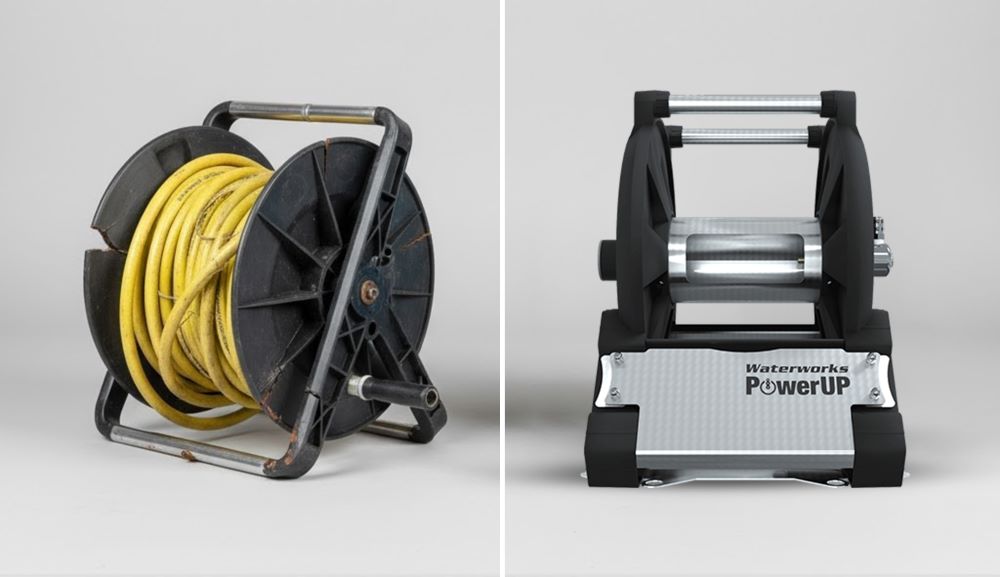

Cheap reels, poles, or fittings might look like a good deal, but in professional window cleaning, low-grade materials cost more over time.

Poor-quality frames corrode quickly, clamps loosen, and hoses kink or split — leading to downtime, leaks and unnecessary replacements.

When you invest in equipment built for commercial use, you save time and protect your system’s reliability.

Waterworks supplies premium-grade manual and electric hose reels built from powder-coated or stainless-steel frames, and genuine window cleaning poles trusted by UK professionals for their balance, reach and rigidity.

Signs Your Equipment Needs an Upgrade

- Rust or corrosion on frames and fittings.

- Hoses that twist, kink or leak under pressure.

- Clamps that slip or fail to lock during use.

- Brushes that leave streaks even after filter maintenance.

If you notice any of these, it’s time to invest in professional-grade tools built for reliability and safety.

How to Avoid This Mistake

- Check build materials before purchase. Prefer stainless-steel or powder-coated aluminium frames — they resist rust and heavy daily use.

- Confirm reel capacity and hose compatibility. Overloading a reel reduces performance and lifespan.

- Buy from trusted professional suppliers. Waterworks ensures every product is field-tested for daily commercial use.

Recommended Waterworks Products

Shop Window Cleaning Reels — durable manual, electric, and double-stacker options.

Window Cleaning Poles — industry-leading poles designed for strength, control, and lightweight handling.

Mistake #3 – Skipping Essential Safety Gear and Accessories

Even the most skilled window cleaners overlook safety from time to time — until a simple mistake turns into costly downtime.

Forgetting to use harnesses, pulleys, or secure fittings can damage your gear, put operators at risk, and even void insurance coverage.

Every professional setup should include proper personal protective equipment (PPE) and durable accessories to keep systems running safely.

A missing HD Security Pulley or loose connector might seem minor, but it can stop a day’s work instantly and cause avoidable expenses.

Why Accessories Matter as Much as Systems

- Safety first: Pulleys and connectors keep hose lines tidy and prevent tripping hazards.

- Efficiency: Quick-release fittings and hoses save minutes on every job — hours each week.

- Longevity: Protective hose guides and clamps reduce wear and extend system life.

- Professional image: A well-organised setup reflects trust and quality to clients.

How to Avoid This Mistake

- Treat safety gear as essential, not optional. Include harnesses, gloves and pulley systems in every setup.

- Inspect accessories regularly. Replace frayed hoses and damaged connectors before they fail.

- Keep spares on hand. Small parts like clips and hose ends can halt work when missing.

- Buy quality components. Waterworks accessories are engineered for daily commercial use and fit seamlessly with existing systems.

Recommended Waterworks Accessories

Accessories & Window Cleaning Supplies — complete range of hoses, fittings and safety equipment for professionals.

Security Pulley — built to keep hose lines secure and reduce snagging or strain.

Mistake #4 – Ignoring Product Labels and Compatibility

A window-cleaning system works efficiently only when every part — from hose diameter to pump voltage — is perfectly matched.

One mismatched connector or under-rated controller can reduce pressure, waste water, or even damage your equipment.

Many professionals ignore manufacturer labels, assuming “close enough” will work.

In reality, incorrect fittings strain pumps, lower flow rates, and create leaks that affect both performance and safety.

Common Compatibility Errors

- Mixing hose diameters: 6 mm and 8 mm hoses require specific reels and ports.

- Incorrect flow-controller voltage: Using 12 V controllers on 24 V systems risks motor failure.

- Unmatched pump and filtration capacity: Oversized pumps overwhelm small RO/DI units.

- Ignoring pressure ratings: Connectors or clamps not rated for high pressure may burst under load.

How to Avoid This Mistake

- Always read product specifications before buying any component.

- Match by measurement, not appearance — a hose that “looks right” may be off by millimetres.

- Use manufacturer-approved accessories designed for your system type.

- Consult experts when unsure about setup or compatibility.

Recommended Waterworks Resources

Window Cleaning System Builder — design a compatible van or trolley system with expert guidance.

Contact Waterworks Support — speak to a specialist for technical advice before purchase.

By checking compatibility at the start, you’ll save money, extend system life, and deliver consistent, professional-grade cleaning results.

Mistake #5 – Neglecting Maintenance and After-Sales Support

Even the best window-cleaning systems lose performance without regular upkeep.

Resin exhaustion, blocked filters, worn clamps or cracked fittings can all lead to leaks, pressure loss, or complete downtime — costing both time and profit.

Skipping routine maintenance often means small problems turn into expensive replacements.

Professional window cleaners should schedule inspections and keep essential spare parts readily available.

Key Maintenance Practices

- Check resin levels monthly: Replace DI resin when TDS exceeds 010 ppm.

- Flush RO membranes regularly: Prevents mineral build-up and extends filter life.

- Inspect hoses and connectors: Look for cracks, leaks or pressure drops.

- Service pumps and flow controllers: Keeps water delivery consistent and energy-efficient.

How to Avoid This Mistake

- Create a maintenance schedule. Include weekly and monthly checks for filters and hoses.

- Keep critical spares on hand. Replace clamps, seals and connectors before they fail.

- Track system performance. Note changes in pressure or water flow to spot issues early.

- Rely on Waterworks after-sales support. Our UK-based team offers guidance and genuine replacement parts for every system.

Recommended Waterworks Products

Window Cleaning Spares — replacement filters, connectors and fittings for all systems.

Contact Support — speak with a technician for maintenance or installation help.

Regular maintenance and timely support extend equipment life, keep jobs on schedule, and ensure every clean meets Waterworks’ professional standard.

Summary — Build a System That Performs

Avoiding these five common mistakes helps extend the lifespan of your tools, maintain consistent results, and reduce wasted costs.

When you choose professional-grade systems, pure-water technology, and reliable accessories, every job becomes faster, safer, and more efficient.

At Waterworks, we don’t just supply equipment — we help you design complete window cleaning systems that perform day after day.

Frequently Asked Questions

What cleaning products should you avoid?

Avoid using detergents, ammonia-based cleaners, or unfiltered tap water. These leave mineral deposits and streaks on glass.

Professional cleaners achieve the best results with pure water produced by RO/DI or DI systems like those supplied by Waterworks.

What are the do’s and don’ts in professional window cleaning?

Do: Use pure-water systems, regularly inspect hoses and fittings, and follow safety protocols.

Don’t: Use harsh chemicals, ignore TDS readings, or operate without proper accessories such as pulleys and harnesses.

What is the number one hazard faced by professional window cleaners?

Falls and slips are the biggest risks when working at height. Using a water-fed pole system minimises this hazard, allowing you to clean safely from the ground — one reason many professionals upgrade to Waterworks systems.

What do professional window cleaners use to clean their windows?

Professionals use pure-water window cleaning systems with telescopic poles, pumps, and filtration units.

These deliver deionised water through a brush head to remove dirt and dry streak-free — no chemicals required.